Vacuum fruit juice concentrate machine

Fruit juice concentrate machine is a common equipment in fruit juice production line. It is used after fruit juice extraction, degassing or clarification process, to make concentrated fruit juice, which is the raw material to make various juice drinks.

Fruit juice concentate machine adopts vacuum concentration working principle. The short concentration time won’t destroy the active ingredients in the heat sensitive materials. The concentration ratio can reach up to 1.4.

The concentrator can work under normal and negative pressure in continuous or intermittent status. It has wide versatility, which applies to various materials. Vacuum fruit juice concentrator are used in pharmacy, food, chemical industry for the liquid concentration, distillation, recovery of organic solvents, and evaporation recovery of waste water.

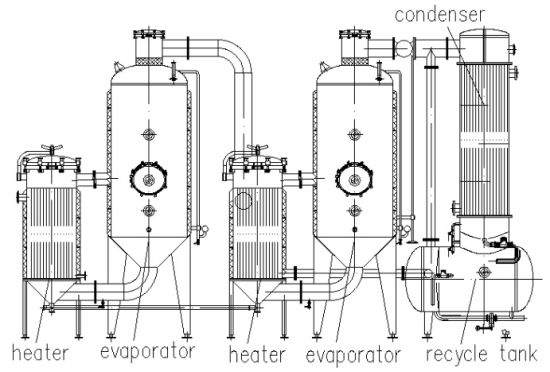

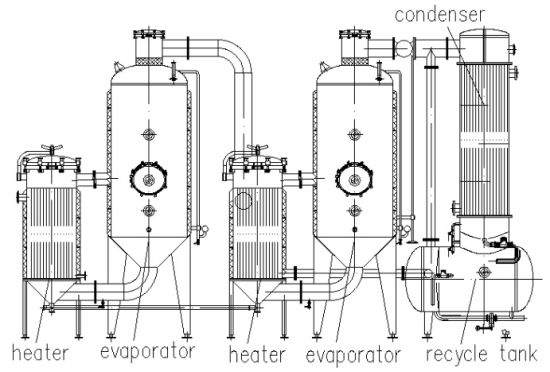

Vacuum fruit juice concentrator structure

Vacuum fruit juice concentrate machine is composed of vacuum concentrate tank, vapor liquid separator, condenser, liquid receriver, and the vacuum system. The parts in contact with the fluids are made of 304 or 316L superior stainless steel, and meet the GMP mechanical standard.

According to customers’ requirement on the production technology, the concentrator tank can be equipped with stiring system, as well as explosion-proof motor, brand motor, and variable frequency speed motor. Both steam heating and electric heating is aviliable.

Vacuum fruit juice concentrator structure working principle

The vacuum concentrate tank is installed with jacket and insulation layer. The vapors and heat transfer oil heat up the jacket, and the jacket heat up the raw materials to boil. Then, the vapor liquid separator separate the foams with active ingredients from the secondary steam, and send them back to the cans. The condenser collect the rest of steams to the liquid receiver.

Vacuum fruit juice concentrator Parameters

|

Model |

300L |

500L |

1000L |

1500L |

2000L |

|

Evaporative capacity kg/h |

60 |

100 |

200 |

300 |

400 |

|

Heating area m2 |

1 |

1.57 |

2.5 |

3.5 |

4 |

|

Condensation area m2 |

2.2 |

4 |

6.5 |

8.5 |

10 |

|

Steam consumption kg/h |

72 |

120 |

240 |

360 |

480 |

|

Cooling water consumption t/h |

2 |

4 |

6 |

8 |

10 |

|

Dimesions m |

2*1*2.3 |

2*1.2*2.6 |

2.7*1.9*2.9 |

3*1.7*3 |

3.1*1.8*3 |

Warranty policy

-

All our products have 1 year warranty period since the acceptance date.

-

Installation and maintainence. Since the delievery date, we provide lifelong free technichal support, including technichal consulting,

-

In the warranty time, we provide three guarantees for the equipment: maintenance, replacement and return. We are responsible for any quality problems arising in the warranty time without misoperation.

-

After the warranty time, we still provide paid maintenance service, and supply spear parts in the the most favorable price.

Get in Touch Now!