Citrus Essential oil extractor machine

What is citrus essential oil used for?

Citrus peels takes up 22-28% of the citrus fruit weight. It can be divided into exocarp, sarcocarp and endocarp. The exocarp is full of oil vacuoles, which contain pigment and essential oil. Citrus oil is a kind of natural perfume oil. It is transparent with pleasant orange fragrance. Citrus essential oil contribute to removing phlegm, cough and asthma, digestive juice secretion, analgesia, gallstone dissolution, bacteriostasis, inflammation diminishing, free radicals removing.

Citrus oil is usually used as the flavoring agent in drinks and pastries. Besides, It also plays an important role in many commodities like florida water, perfume, toothpaste, toilet soap, etc. Currently, the annual global demand of citrus essential oil is around 18000 tons, 60%-70% of which is for food industry use, others are used in cosmetics, aromatic detergent, and pesticides. Meanwhile, the citrus essential oil market grows at the speed of 18% every years.

Citrus essential oil extractor machine

AGICO citrus essential oil machine adopts cold-pressing method. It applies to different citrus fruits like oranges, navel oranges, lemons and grapefruits. It can extract and gather citrus essential oil automatically, with high extraction rate and low waste.

How does a citrus essential oil machine work

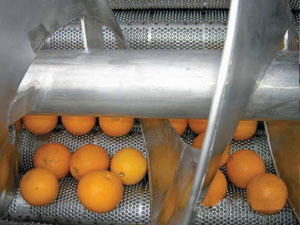

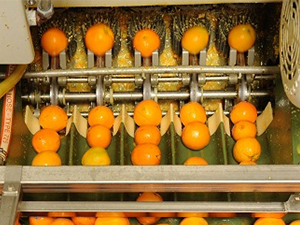

After cleaning, the citrus fruits was fed into the oil extractor machine by a feed scraper. In the oil extractor machine, there are needles on the rotating rollers pricking the oil vacuoles on the citruses. Then, a water gun rush the essential oil on the orange surface into a collecting tank. After that, the orange oil was transmitted to separator to separate oil and water.

After essential oil extraction process, the citrus fruit can still be fed into the juice production line to extract orange juice.

needles on the rotating rollers

Specifications of citrus essential oil machine

|

Type |

Production capacity(t/h) |

Boundary dimension (mm) |

Motor power (kw) |

|

TCM-1 |

3-5 |

3650*1100*1500 |

4.75 |

|

TCM-2 |

5-10 |

5000*2300*2000 |

9 |

Advantages of citrus essential oil extractor

-

Linear type design, easy to install, operate and maintain.

-

The pneumatic and electric parts adopts components from famous brands.

-

High automation and intellectualization. High extraction rate and low waste.

-

The essential oil machine can work in a orange juice production line or independently.

Cold pressing method for essential oil extraction

Citrus fruit sorting and cleaning

The essential oil in different citrus fruits have different properties. Don’t mix different citrus fruits together. Besides, choose fresh citruses without mildews, and clear up the dirt and impurities with water flow.

Essential oil extraction and separation

The cleaned citrus fruits are conveyed into essential oil extractor machine by feed scrapers. There are rotating rollers with needles that prick the oil vacuoles on the citrus surface, and the essential oil ooze out. Then the water sprayers wash the oil into the collector. After that, the oil and water are separated under the centrifugal force.

Essential oil refining

The separated essential oil may still contain some water and peel wax. They need further refining. The simplest way is to place the crude essential oil at the temperature of 5-8℃ for 5-6 days. In this way, most remnant water will precipitate out, and the peel wax will seed out under low temperature. Expel the water and wax at the bottom and you will get fine citrus essential oil.

Essential oil packing and storage

The terpenes in essential oil are easy to be oxidized under the sunlight. So it is necessary to fill it in airtight container and keep in dark place.

Get in Touch Now!

needles on the rotating rollers

needles on the rotating rollers