Orange Juice Processing: Orange Juice Making Process and Equipment

Orange juice, one of the most popular juices worldwide, is loved by consumers for its delicious taste and rich nutritional value. Not only does orange juice have a sweet and tangy flavor, but it also contains abundant nutrients. It is rich in Vitamin C, a powerful antioxidant that strengthens the immune system, helps fight off diseases, and promotes collagen production, keeping the skin elastic and glowing. Additionally, orange juice contains flavonoids and other antioxidants, which help reduce the risk of cardiovascular diseases and lower inflammation. The potassium content plays a significant role in maintaining normal heart function and stabilizing blood pressure. Furthermore, the citric acid in orange juice helps promote gastrointestinal motility and aids digestion.

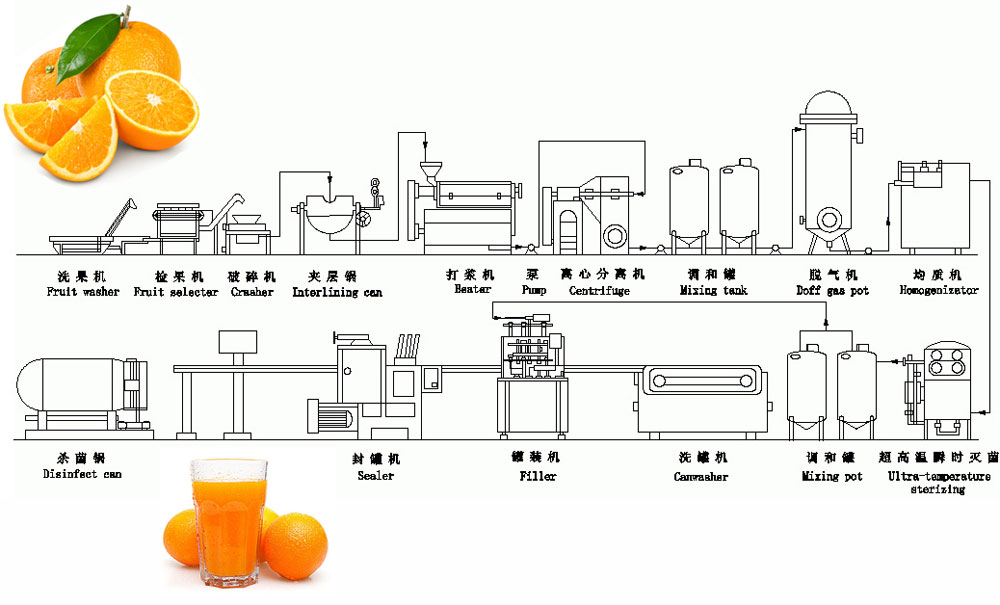

So, how is orange juice made? From the harvesting of oranges to the final bottled juice, the entire orange juice processing relies not only on efficient

production lines but also on various professional equipment. Below, we will detail the orange juice making process and the equipment required for juice production.

Orange Juice Making Process

The process of making orange juice involves several key steps, including fruit handling, juicing, filtering, pasteurization, and packaging. Below is the main process of orange juice production.

Raw Material Preparation and Washing

The first step in orange juice processing is selecting fresh, ripe, and pest-free oranges. High-quality oranges are the foundation for producing delicious juice. Once the oranges are selected, they undergo strict sorting and washing to remove surface impurities and contaminants. The washing step is crucial, and specialized

fruit washing machines are used. These machines clean the oranges by spraying, rolling, and using other methods to remove dirt, pesticide residues, and microorganisms, ensuring the safety and hygiene of the juice. After washing, the oranges are further sorted to ensure only those meeting quality standards move on to the next step.

Juicing Process

After the washed oranges are sent to the juicer, this is one of the most critical steps in orange juice production. The juicer presses the oranges to extract the juice. Modern juicers use automated equipment that can adjust juicing pressure based on the size and hardness of the oranges, ensuring maximum

juice extraction. Common juicing equipment includes screw juicers and centrifugal juicers. A screw juicer uses a screw propeller to press out juice from the oranges, while a centrifugal juicer uses high-speed rotation to generate centrifugal force, separating the juice from the pulp. The cleaned oranges are placed into the juicer, and through the juicing process, the juice is fully extracted.

Juice Filtering and Pulp Removal

The extracted orange juice contains a significant amount of pulp and peel, so filtering equipment is used to remove these. Common filtering equipment includes vibrating screens and plate-and-frame filter presses. The vibrating screen uses vibration to remove large particles, while the plate-and-frame filter press further removes fine impurities, clarifying the juice. The filter separates the pulp from the juice, ensuring the juice is clear and smooth. Depending on the requirements, the filter can adjust the mesh density to achieve different levels of juice clarity.

Pasteurization (Heat Treatment)

To ensure the hygiene and safety of the juice and extend its shelf life, the juice must undergo pasteurization using a pasteurization machine. Pasteurization involves heating the juice at a high temperature (usually 90-95°C) for a short period to kill bacteria and microorganisms while retaining the juice's nutritional content and natural flavor. Common pasteurization equipment includes high-temperature short-time (HTST) pasteurizers and ultra-high-pressure pasteurization devices. HTST pasteurizers rapidly heat the juice to a specific temperature to kill microorganisms, while ultra-high-pressure devices use high pressure to achieve the same purpose.

Cooling and Storage

After pasteurization, the juice needs to be quickly cooled to room temperature for further processing and packaging. In this step, cooling equipment plays a crucial role in preserving the juice's freshness and nutritional value.

Juice Concentration and Dilution (Optional)

For juices that require longer shelf life, the juice is typically concentrated using a concentrator to remove some of the water content, reducing the volume. This concentrated juice needs to be diluted before sale to restore it to its normal drinking concentration.

Packaging and Sealing

Finally, the processed juice is sent to an automatic packaging machine, where it is sealed in bottles or cans. Modern packaging equipment can adapt to various packaging formats (bottles, cartons, etc.) to meet market demand and efficiently complete the packaging process, ensuring product integrity and safety. Common filling equipment includes atmospheric filling machines and vacuum filling machines. Depending on the packaging requirements, the juice is filled into glass bottles, plastic bottles, or carton packaging.

Equipment Required for Orange Juice Production

Various specialized equipment plays a crucial role in orange juice processing. The followings are some common machines used in the production process.

Juicer

The juicer is one of the core pieces of equipment in the orange juice production line, used to extract juice from oranges. There are various types of juicers on the market, such as pressing-type juicers and centrifugal juicers. The appropriate type is selected based on the production needs.

-

Screw Juicer: The core component is a screw conveyor, usually made of stainless steel, with a smooth surface and a specific pitch. When oranges enter the juicer, they first pass through a crushing device that breaks them into small pieces to facilitate the juicing process. Then, the crushed orange pieces are transported to the screw conveyor. As the screw turns, the orange pieces are gradually pushed toward the outlet. The screw pitch decreases, compressing the space, and the oranges experience increasing pressure. Under the strong pressure, the cell structure of the orange is destroyed, and juice is fully extracted, flowing out of the juicer, while the pulp is expelled from the waste outlet.

-

Centrifugal Juicer: A centrifugal juicer features a high-speed rotating drum with small holes evenly distributed on the drum's surface. The oranges are first pre-crushed before entering the drum. As the drum spins at high speed, centrifugal force pushes the juice and pulp toward the drum's edge. The juice is expelled through the small holes into a collection container, while heavier materials like pulp and seeds remain adhered to the drum's wall and are expelled after continued rotation.

Juice Filter

Filters are used to remove pulp and impurities from the juice, ensuring the purity and taste of the final product. High-efficiency filters can effectively remove skin and seeds, ensuring a clear product.

Vibrating Screen: A vibrating screen consists of a screen mesh, vibration motor, and support device. The mesh has varying degrees of fineness depending on the filtering precision required. When the juice is delivered to the vibrating screen, the motor produces high-frequency vibrations. As the juice vibrates on the screen, larger particles such as pulp and seeds are unable to pass through the mesh and are moved toward the edge of the screen, eventually being expelled through a waste outlet. Smaller juice particles pass through the mesh and are collected in a container below.

Pasteurization Machine

A pasteurization machine uses heat treatment to kill bacteria and microorganisms in the juice, ensuring product safety and extending shelf life. This equipment is typically used during the sterilization stage of juice production.

Cooling System

After pasteurization, a cooling system rapidly reduces the temperature of the juice to prevent high temperatures from affecting the juice's quality.

Concentrator

For juice that needs to be concentrated, a concentrator removes some of the water content, reducing the volume for easier transportation and storage.

Automatic Packaging Machine

The automatic packaging machine is used to bottle or can the juice and is an essential part of modern juice production lines. It efficiently completes the packaging process, ensuring the seal and safety of the juice product.

Through the above series of steps, using various specialized equipment, fresh and delicious orange juice is made. This is how orange juice is made, and the orange juice processing process in full. Making orange juice is a complex process, involving multiple steps, each requiring efficient and precise equipment support. From fruit washing and juicing to filtering, pasteurization, and packaging, each piece of equipment plays a vital role. As technology continues to evolve, orange juice processing equipment becomes increasingly intelligent and automated, improving production efficiency and product quality while meeting the market's demand for high-quality orange juice.

If you want to learn more about orange juice processing equipment or have related needs, feel free to consult our professional advisors. We will provide you with the most professional advice and support.

Get in Touch Now!