Orange juice production line

Orange juice is the most popular drink in the world. It has good taste and nutritive value.

-

It contains vitamin c, carotene, citric acid, cellulose, pectin and various minerals.

-

The rich vitamin C and carotene can help prevent cardiovascular disease.

-

The cellulose and pectin can improve intestinal gurgling.

-

Drinking orange juice frequently can improve your looks and lower the risk of cancer.

According to market statistics, orange juice remain as the king of global juice market, taking up 46% of the juice market share. With the increase of people’s disposable income and health awareness, the orange juice consumption will keep growing. Therefore, orange juice production is a promising business. To engage in orange juice production, you need to build a orange juice processing line.

An orange juice production line contains the following equipment and processes. They cover the process of fruit sorting, washing, conveying, peeling and extraction, fruit juice filtration, degassing, sterilization, homogenization and filling. Not all these products are required in an orange juice production line, you can make your own combination according to your needs.

-

Fruit sorting machine

-

Fruit elevator

-

Fruit washing machine

-

Fruit peeling and extracting machine

-

Juice filter

-

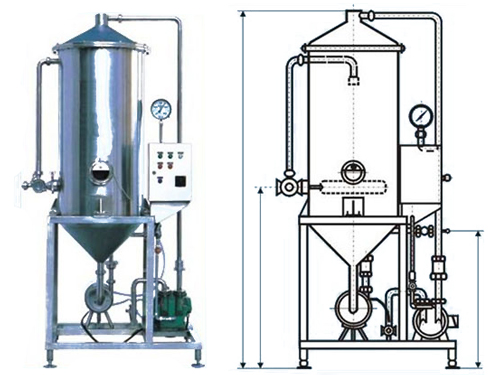

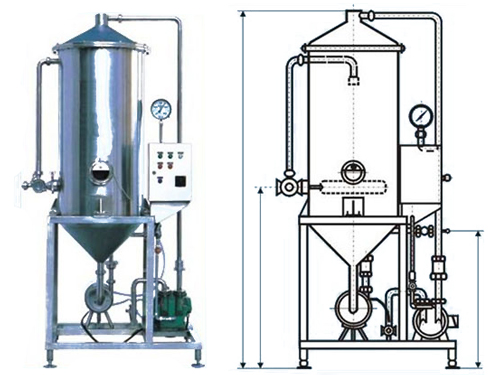

Vacuum Degasser

-

Plate UHT Sterilizer

-

Metal can filling machine

Orange raw material selection

To ensure the orange juice quality, we need to choose fresh and fully-ripe oranges with good flavor, abundant juice but no diseases or pests.

To improve working efficiency and save labor, we provide rolling bar fruit sorting machine. It applies to various kinds of round and oval fruits. They rotate freely and move forward on the stainless steel roller, during which workers can observe every side of the orange and pick out the unqualified ones. The rotating speed of the rolling bar is adjustable.

Orange raw material conveying

To transmit raw materials from one processing equipment to the next and realize continuous production, fruit elevators or conveyors are necessary. It can be used before fruit sorting machine or between any 2 fruit processing equipment. There are scrapers on the transmission belt that can hold the fruits and lift them from lower to higher place.

TICO fruit elevator adopts a stepless speed variation motor. We provide different transmission device, including stainless steel connected plate, food grade plastic board, and food grade compound robber belt. Besides, sprayer and water collector can be added according to needs.

Orange raw material washing

To remove the pesticide residues on oranges, we need to clean them in water with detergent, and rinse them with spray or running water. After cleaning, you can select the oranges once more, and eliminate those diseased, damaged or unripe fruits.

In large-scale fruit juice production, fruit washing machine is often used to improve the cleaning effect. The surfing type fruit washing machine adopts blowers to make the water tumbling. So the running water scours the surface of orange and wash the dirt off. Then, the oranges will be lifted by the scraper, under which there are brushes and sprayers scour the oranges once again.

Orange juice extraction

The peels of citrus fruits contains essential oil, taro withered and terpene that have unpleasant tastes. And the endocarp and seeds contain flavonoid like naringin and limonin. After heating, these substance will dissolve in the orange juice and make it taste bitter. For these reason, crushing and pressing method doesn’t apply to citrus fruits. Their juice are extracted by tapered mold.

TICO fruit peeling and extracting machine integrate the function of peeling, coring and slicing. It adopts special conical screen who has 2-3% larger extraction rate than traditional turbo structure. The paring knife can be adjusted according to the fruit shape to achieve the best peel thickness. The peeling rate can reach up to 98% with little waste.

Orange juice filtration

The extracted orange juice contains some suspended solids. They not only influence the appearance of fruit juice, but also make it easy to go bad. So filtration is a necessary process. For cloudy juice, filtration aim to remove the large suspended particles with no damage to the color, flavor and taste. For clear juice, they need fined filtration after rough filtration, which remove all suspended solids and colloidal particles who may cause precipitation. According to the production demand, we choose pressure filtration and vacuum filtration.

Blending and sugaring

To improve the orange juice taste and make it meet customers’ preference. We need to blend and add sugar to adjust the ratio of sugar and acid. The best ratio of sugar and acid is between 13/1 and 15/1, or it would loose the original flavor of orange juice.

There are 2 ways to adjust the ratio of sugar and acid. Add granulated sugar and edible acid, or mix different kinds of fruit juice. Fruit juices are different in colors, tastes, sugar and acid content. To mix 2 or more fruit juice in certain proportions, we can get fruit juice with new flavor.

Orange juice Degassing

The oxygen, nitrogen and carbon dioxide contained in the fruit cell will dissolve in the orange juice during processing, or attach to the fruit particles. Besides, the contact of fruit juice and air in processing will increase the gas content. The oxygen will damage the vitamin C. And their reaction with various compositions in the juice will destroy the flavor and color. These adverse effect will be strengthened by heating. So, before pasteurization, we need degassing to remove the excess oxygen. The degassing technology includes vacuum method, nitrogen exchange method, Enzyme method and antioxidant process.

Orange juice homogenization

Homogenization is an additional process to make cloudy orange juice, usually for those packed in glass bottles. After passing through the homogenizer, the particles in the fruit juice get further crushed and unified. The homogenization promote the extrudation of the pectin, and make it mix uniformly with the fruit juice. In this way, we can get cloudy juice with no condition of separation or precipitation.

High-pressure homogenizer and colloid mill are common equipment for this process. In a high-pressure homogenizer, the suspended particles get crushed by the high pressure. They are fed through small holes whose diameter is 0.002-0.003 by force. After that they become finer particles and get distributed in the orange juice uniformly.

Orange juice Pasteurization

Pasteurization can eliminate the spoilage organisms in orange juice, and passivate the enzymes that can cause chemical changes. But heating may damage the quality of the orange juice. So, to achieve the sterilization effect, and reduce its effect on the juice quality, we need control the heating temperature and time. Usually, we adopts HTST sterilization, 93℃±2℃ for 15-30s, or over 120℃ for 3-10s.

Filling and cooling

The pasteurized orange juice (the temperature is about 85℃) are pumped into the charging basket and filled into the cans. The orange juice should be kept in the charging basket for less than 2min to reduce the flavor change. After filling and sealing, the orange juice cans are placed upside down for 20 min to sterilize the cover with the high temperature of the orange juice. Then, cool the orange juice cans by spraying cold water and lower the temperature to under 38 ℃. The excess heat can help the dry the outside and prevent rusting.

Get in Touch Now!