How to make orange juice in factory?

In factory, original orange juice is made by the following processes:

-

Collect and check the oranges

-

Clean up the oranges

-

Select qualified oranges

-

Orange juice extraction

-

Orange juice filtration

-

Orange juice sterilization

-

Get original orange juice

To make concentrated orange juice, you need additional processes:

-

Concentrate the original orange juice

-

Cool the concentrate orange juice down

-

Fill and package the concentrate orange juice

-

Freeze the concentrate orange juice

How to make concentrated orange juice in factory?

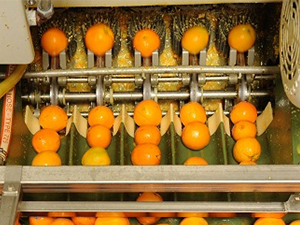

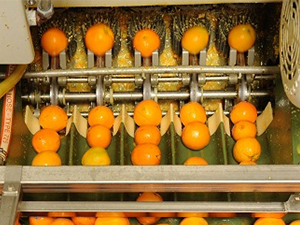

Orange selection and storage

To ensure the quality of orange juice, staffs need to choose those oranges without bitter tastes, and remove those damaged or unqualified fruits. The staffs sort the oranges with a roller type fruit sorting machine. The oranges are preserved in a warehouse.

Orange cleaning

Usually, they add 1-2% sodium hydroxide and disinfectant to the water tank.

-

First, they dip the oranges in water for a while.

-

Then, rinse the oranges with roller brush.

-

Next, pray the oranges with chlorinated water (with 10-30mg/L).

-

At last, spray the oranges with clean water.

Orange peel unoil

The cleaned oranges are conveyed to the needle unoil machine. It pierce the orange peels. When the oil escape from the orange peels, it is washed away by the spray water.

A disc centrifugal separator can separate the orange oil from the water. The residue liquid will return back to the unoil machine through a circulating pipe and serves as spray water.

Orange juice extraction

The juice extractor for kernel fruits, stone fruits, and berries are not suitable for unoiled fruits. Generally, oranges are extracted by in-line juicer, brown type juicer, Anderson juicer. The juicer should prevent pericarp oil, white cortex, and cysts from getting into the orange juice, and prevent the seed broken.

Remove the orange pulp

The original orange juice extracted by the juicer still contains orange pulp. A fruit pulper machine can filter out the large particles in orange juice.

Orange juice degassing

Original orange juice is easy to oxidize, thus causing the loss of color, tastes, and vitamin C. Degassing can preserve the quality of orange juice. Fruit juice degassers have centrifugal spray, pressurized spray, and film flow 3 types.

Orange juice sterilization

To preserve the microbial stability of orange juice, they usually adopt 71-72℃ sterilization and corresponding time.

To inactivate the pectin methylesterase and preserve the colloidal stability of the original orange juice, they need to adopt 86-99℃ sterilization.

Orange juice concentration

Orange juice usually adopt freeze concentration method. The concentration stops when the soluble solid takes up 65%.

Package and storage

After the orange juice concentrate at -5~-8℃, it is filled into a barrel coated polyethylene inside. The sealed barrel will placed in a refrigerated storage at the temperature of -25~-30℃.

Add water to the concentrated orange juice

The above displayed how to make concentrate orange juice in factory. But to make drinkable orange juice sold in the market, they need to add water to the concentrated juice, as well as some additives like sugar, syrup, essence, thickener, preservatives, etc.

Many orange juice manufacturers buy concentrated orange juice from factories and make orange taste drinks with it. Orange juice concentration can reduce the volume, save transportation cost, and inhibit microbial activity.

AGICO is a professional fruit juice production equipment manufacturer. We provide complete orange juice production line with the function of orange sorting, cleaning, citrus oil extraction, orange juice extraction, degassing, sterilization, filling and packing, etc. Welcome to contact us to get the price and other information.

Get in Touch Now!